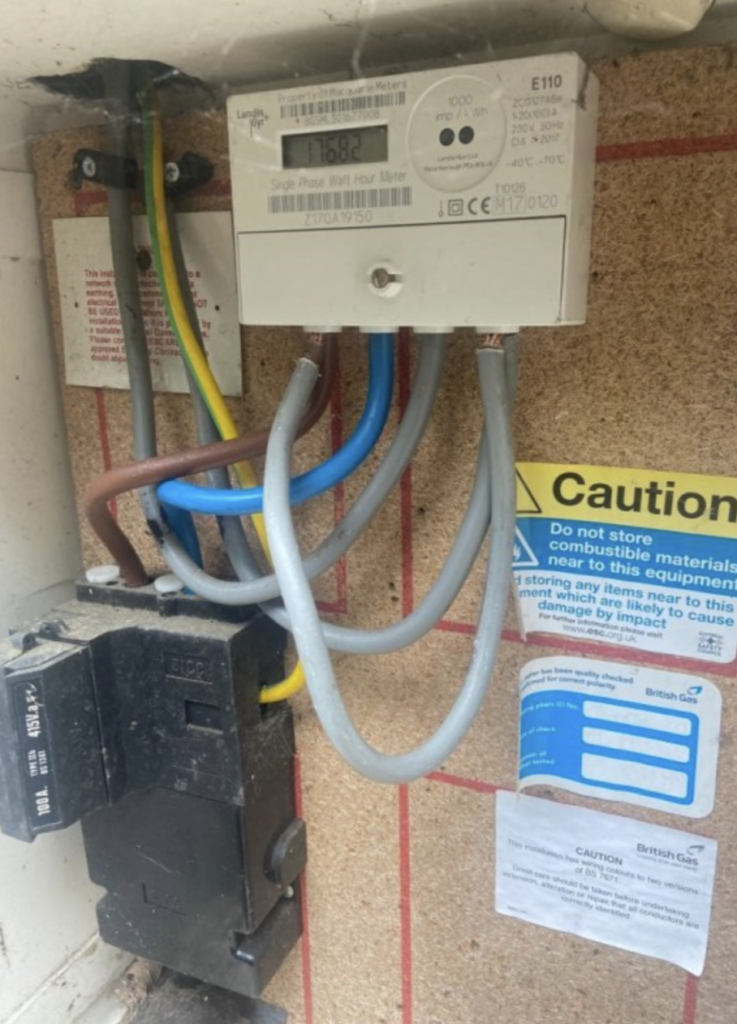

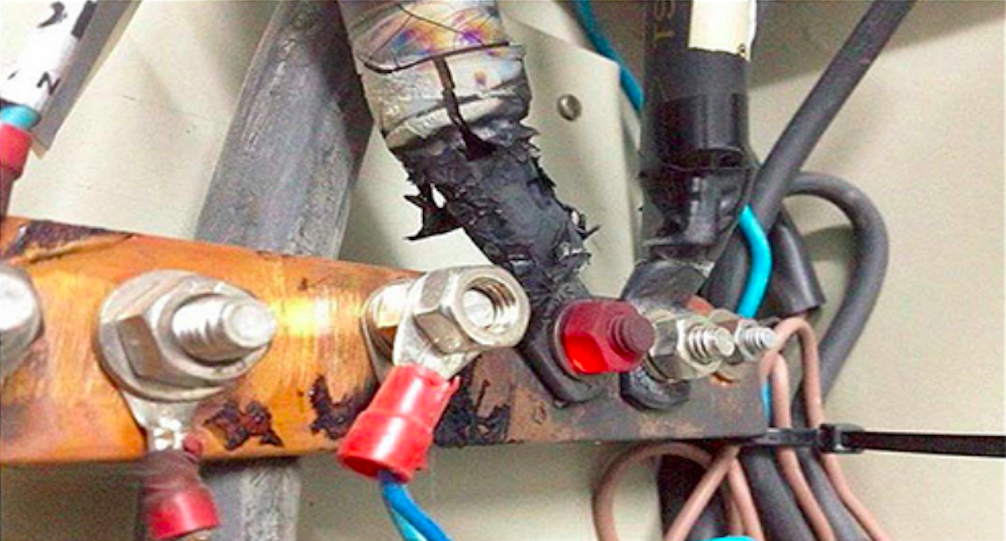

A fuse is generally accepted to be the simplest form of protection device used to avoid damage to an electrical system by excess electrical current. This view stems from the simple construction of the wire type fuse and often leads to the assumption that the operation of a fuse is also simple.

In general terms, the fuse is an electrical conductor, which melts (disintegrates) when subjected to the flow of excessive levels of ‘fault’ electrical current and due to disintegration subsequently interrupts the flow of the fault current. The fuse is then irreparably damaged and can be viewed as being forfeited in the process of protecting its parent electrical system. Thomas Edison acknowledged this and described the role of the fuse as a ‘weak link’ in an electrical circuit.

Besides interrupting fault currents, a fuse should conduct current for all conditions except those classed as faults, hence a fuse is assigned a trip/operation rating so for currents magnitude below the rating, all is good and for current magnitudes above the rating (fault currents, operation of the fuse is triggered.

After operation a fuse should present a high electrical resistance to the flow of electrical current. These attributes are fundamental to the role of the fuse but are commonly overlooked by all but the specialist.

More complex attributes of fuse operation, of interest to fuse designers and specialist users, are the requirements to avert potentially circuit-damaging disturbances (voltage transients) generated during disintegration and furthermore to quickly force current interruption (current limiting). These and other attributes are important in the role of semi-conductor and high breaking capacity (HBC) fuses.

Ohm’s law states that the electrical current flowing through a conductor from one point to another is directly proportional to the charge potential (voltage) and indirectly proportional to the electrical resistance between to the two points of the conductor. Hence in general, the defining parameter in the dynamic operation of an electrical fuse is electrical resistance which by nature defines different time domains of operation, i.e.

Long time operation (tens of milli-seconds) – Low over fault current

Short time operation (milli-seconds) – general fault currents

Very short time operation (micro seconds) – Very high fault current – short circuit fault current

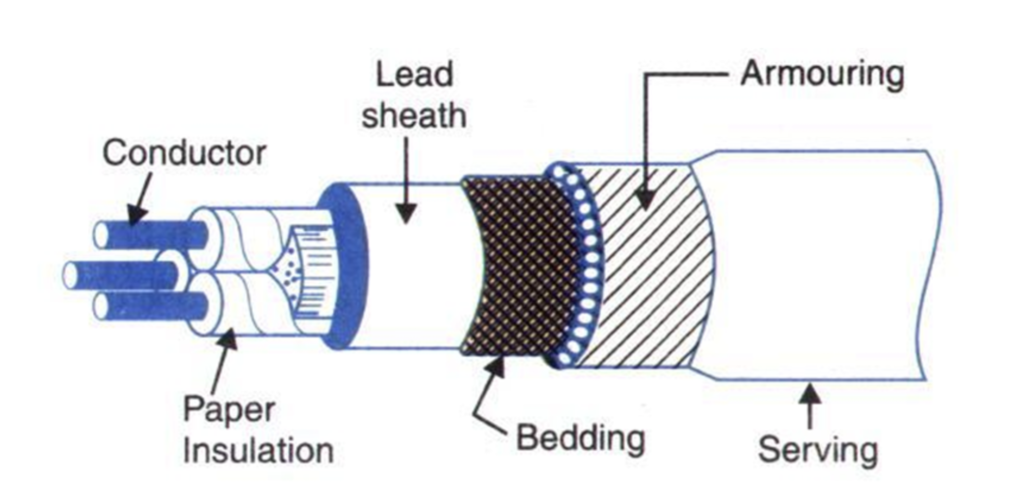

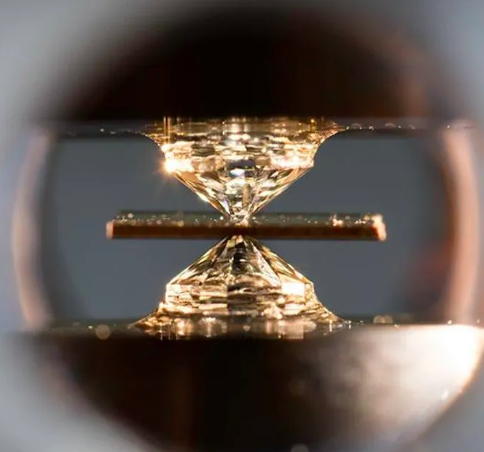

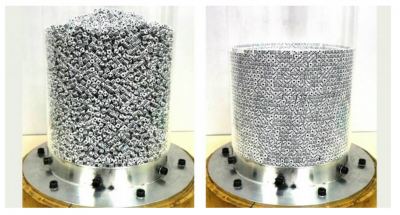

As introduced a fuse in simple terms is but a ‘link’ of conductive material, most often silver or copper wire and the aim of a designer of electrical fuses is to develop a fuse link which operates efficiently in each of the time domains. To accomplish this the designer may for example, alter the shape of the fuse link from its nominal cylindrical from, or may add physical entities to immediate environment of the fuse to enhance beneficial and reduce harmful phenomena in the dynamic process of fuse operation.

To revert to the layman concept that in operation a fuse link is that it simply ‘melts’, well yes this is somewhat correct understanding, however in the micro domain the act of ‘melting’ is a very slow process and in the general scope of fuse operation is not the key driver of fuse operation.

We will discuss this further in future articles.

Eur Ing Dr Robert Brown (Robert) is a Consultant Engineer in the fields Electrical Electronic and Control Engineering. Robert is also an accomplished professional Expert Witness having prepared and presented many court compliant reports and presented oral evidence within the High Court, Crown Courts and County Courts.

For further information please contact Robert via;

Email,…robert.brown@frasergeorge.com or robertbrown@robertbrown.uk.com

Tel Land: +44 (0)1777 709175

Tel Mobile: +44 (0) 7976250624