Good morning,

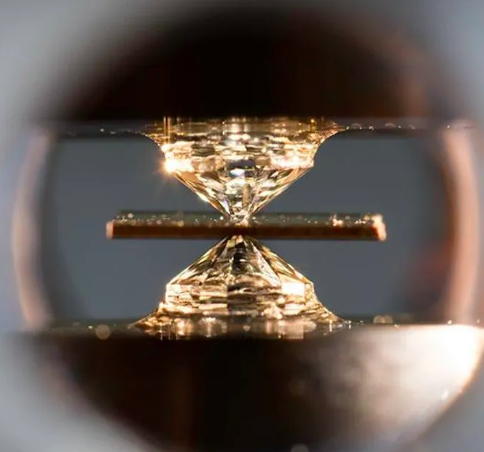

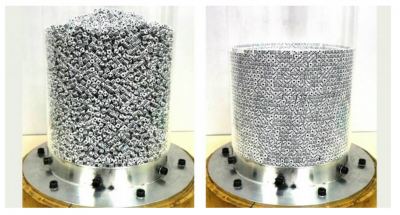

Phase 2 of building a bench top magnetic / eddy current drive coupling.

This is a magnetic coupling; the edit current coupling is Phase 3.

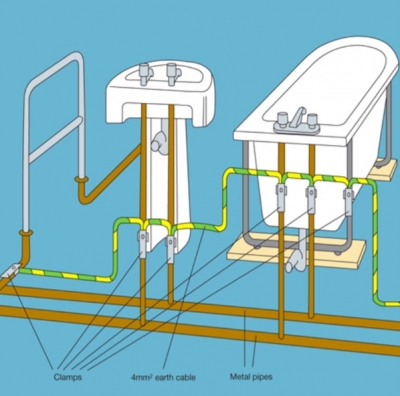

The purpose,… as bench top apparatus to test and configure a differential radial speed monitor and over speed alert system. .

Anyhow the coupling comprises of two sets of six (6) neomollidenium magnets radially spaced and polar opposed.

So given the adage “like poles repel and unlike poles attract, when the drive side of the coupling rotates the non-drive side will rotate in sympathy i.e. since the magnets are polar opposed, fundamental they move under the magnetic force of repulsion.

The drive and non-drive radial speed, i.e. either side of the coupling,…. will always be different since the non-drive side is always moving away from the drive side, fundamentally “cause and effect”. The difference in speed is referred to as ‘slip’.

Magnetic / eddy current drive couplings offer the benefits

• Increased process system reliability.

• Lower maintenance cost for motor, seals and bearings.

• Reduced operational downtime.

• Substantial energy savings.

• Extended life of critical productive assets

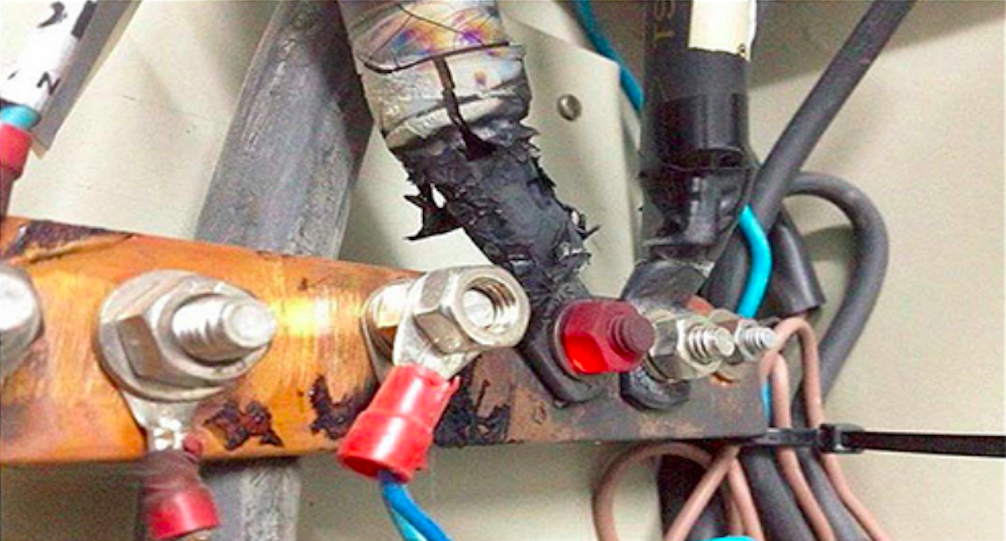

However, in the eddy current coupling radial speed sensing is paramount since given an overspeed circumstance excess heating of the non-drive, non-magnetic half of the cou0lking can provoke damage and in the extreme case permanent damage of the coupling through the non-drive side melting.

Eur Ing Dr Robert Brown (Robert) is a Consultant Engineer in the fields Electrical, Electronic and Control Engineering. Robert is also an accomplished professional Expert Witness having prepared and presented many court compliant reports and presented oral evidence within the High Court, Crown Courts and County Courts.

For further information please contact Robert via;

Email,…robert.brown@frasergeorge.com or robertbrown@robertbrown.uk.com

Tel Land: +44 (0)1777 709175

Tel Mobile: +44 (0) 7976250624