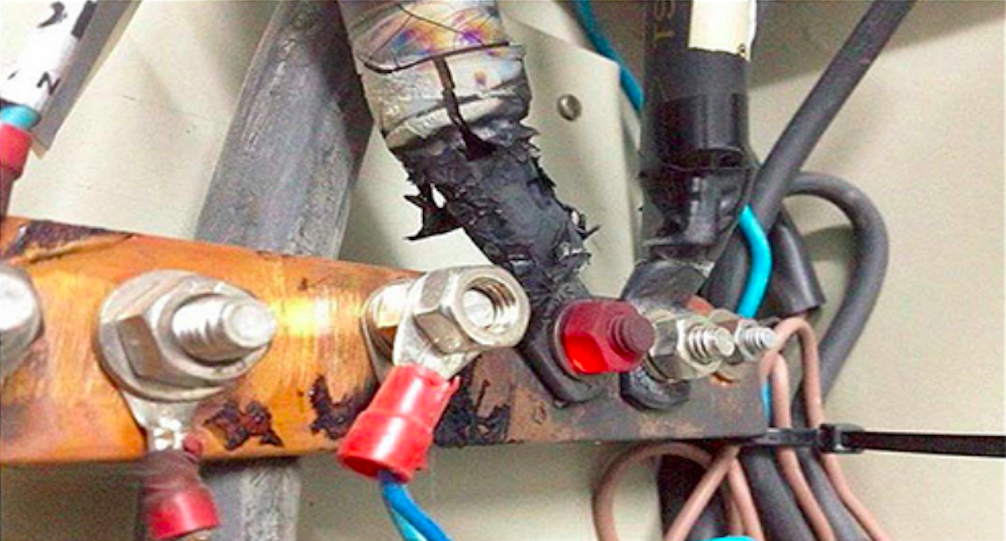

Recently, I wrote of the concept of fuse operation and that in general a layman’s concept is that a fuse link/wire simply ‘melts’ and interrupts the flow of ‘fault’ electrical current.

Within the original discussion the time domains of fuse operation were introduced and the correlation of operation times with levels of fault current, i.e.

- Long time operation (tens of milli-seconds) – Low over fault current

- Short time operation (milli-seconds) – general fault currents

- Very short time operation (micro seconds) – Very high fault current – short circuit fault current

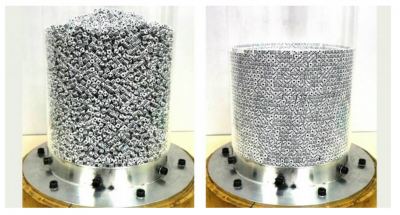

When considered in a micro domain and relative to time, the act of ‘melting’ is a very slow process and in the general scope of fuse operation is not the key driver of fuse operation. Indeed, the act of ‘melting’ encompasses several phenomena which manifest and interact within the dynamics of fuse operation process, i.e.

- Physical expansion of the fuse element due to thermal dynamics

- Thermal dynamics of the fuse environment during phase changes of the fuse element, i.e. solid > liquid > gas

- Surface tension forces

- Skin effect/Current density, inhomogeneous heat distribution of the fuse element during phase changes of the fuse element

- Electrical arcing

- Magnetism

Of the latter, I suggest that key to the successful operation of a fuse is the understanding and control of the phenomena referred to as ‘electrical arcing’. An electric arc, or arc discharge, is a phenomena where the ‘breakdown’ of a gas occurs, such that the gas in ‘breakdown’ provides the basis for the conduction of electrical current.

The air we breathe is a concoction of gases and air in its normal condition is a non-conductor of electricity. On the other hand, when the general attributes of air for example temperature and moisture alter and the air isexposed to intense electrical forces, it can become a conductor of electricity.

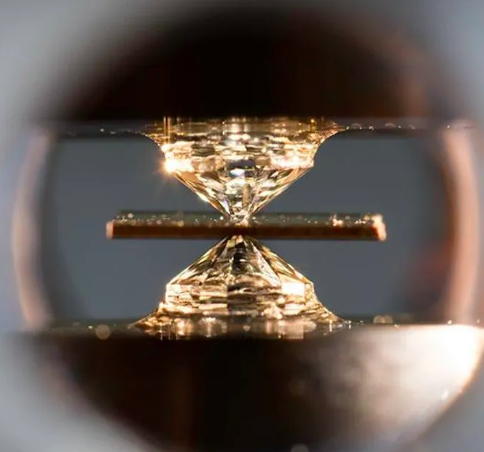

A ‘gaseous conductor’ of electrical current in free air is characterised as a plasma supported between two electrodes and when established emits intense blue/white light and is much elevated in temperature (circa 3,000°C to 20,000 °C).

In operation the temperature of the fuse element/wire rises due to a further phenomenon referred to as ‘Joule Heating’. The phenomenon is also referred to as resistive or ohmic heating. Given continued Joule heating, which occurs in the process of fuse operation due to the passage of fault current, state changes of the fuse wire occur, i.e. at first the physical state of the wire will change from solid to liquid. On a micro scale the state change will not occur along the whole of the length of the wire instantly, yet in parts dependent on the thermal attributes of the fuse environment. In other words, the temperature and phase state/change is distributed along the length of the wire.

Now at some point in time within the fuse operation process, those aforementioned phenomena which make up the perceived ‘melting’, i.e. physical expansion of the fuse element, thermal dynamics of the fuse environment, surface tension forces of a liquid column (the fuse wire in a liquid state), skin effect, current density, inhomogeneous heat distribution of the fuse wire and magnetic phenomena, will provoke the manifestation of a parting, a discontinuity an air gap, within the fuse element.

Logically, at the point of manifestation of an air gap within the fuse wire it could be thought that the fuse had completed its function to ‘interrupt’ the passage of a fault current. However, successful interruption is dependent on the attributes of the ,…

- magnitude of fault current at the point of manifestation of an air gap

- environment surrounding the air gap

- air/gases which make up the air gap

- parent circuit of the fuse

To revert to the correlation of operation times with levels of fault current, it is the case that in long time operation (tens of milli-seconds), low over fault current circumstances, the latter air gap conditions are not beneficial for the formation of electrical arcing whereas in the very short time operation (micro seconds), short circuit fault current circumstance, air gap conditions are advantageous and hence electrical arcing will manifest.

In principle the latter suggests that if electrical arcing evolves that electrical current will continue to flow and hence the fuse operation, i.e. the interruption/clearing of a fault current has ‘failed’. Fundamentally this is so, yet the phenomena of electrical arcing possesses beneficial attributes which if taken-up/capitalised upon by fuse designers, super-fast successful operation of electrical fuses can be ‘engineered’ such that electrical fuses much better electrical circuit protection devices than circuit breakers.

We will discuss engineering super-fast fuse operation in future articles yet conclude here leaving the impression that fuse operations is all but ‘simple’.

Eur Ing Dr Robert Brown (Robert) is a Consultant Engineer in the fields Electrical Electronic and Control Engineering. Robert is also an accomplished professional Expert Witness having prepared and presented many court compliant reports and presented oral evidence within the High Court, Crown Courts and County Courts.

For further information please contact Robert via;

Email,…robert.brown@frasergeorge.com or robertbrown@robertbrown.uk.com

Tel Land: +44 (0)1777 709175

Tel Mobile: +44 (0) 7976250624