Electrical Engineer Expert Witness? Electrical dispute? Do you require the services of an experienced electrical engineer expert witness? CPR 35 expert report? Contact Fraser George !!

Electrical Fires – Consumer Unit Fires

The numbers of consumer unit fires in the home has been noted by fire brigades to be significant. A consumer unit is often affectionately referred to as the ‘fuse box’, yet today most contain miniature circuit breakers (MCB’s), Residual Current Devices (RCD’s) and maybe other electrical protection modules.

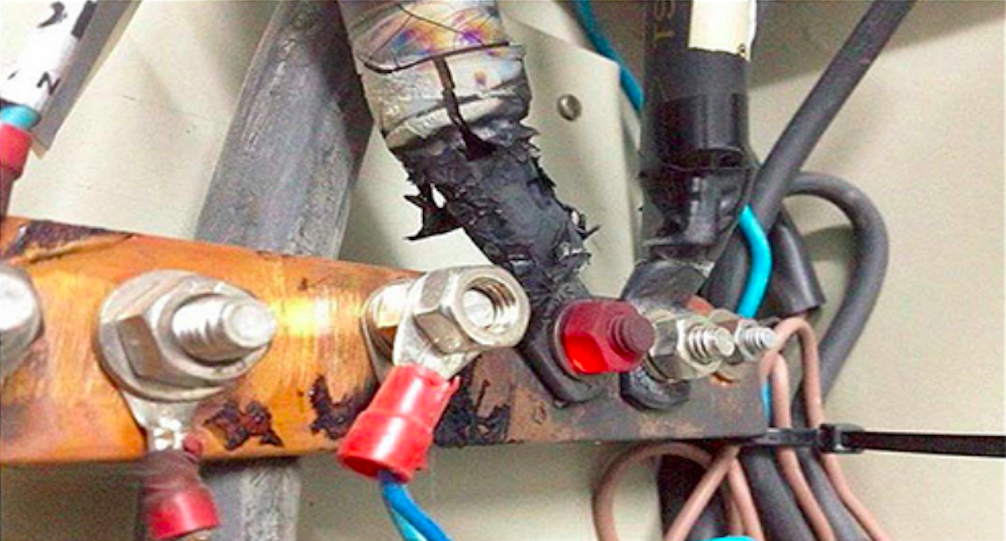

An exacerbating factor in consumer unit fires is that prior to Amendment 3 of BS 7671, the 17th Edition Wiring Regulations published by the Institute of Engineering Technology (formerly the Institute of Electrical Engineers (IEE)), the enclosure of most consumer units were fabricated from plastic. Hence the plastic formed the fuel for fire perpetuation. However what is of importance here is the understanding of the cause of fire ignition, the phenomena that brings about the ‘spark’ the intense heat which provokes the plastic case to melt and then ‘flash‘ to support a flame of fire!

Fundamentally there are two (2) electrical phenomena, which bring about an electrically induced fire, i.e. Joule Heating, commonly referred to as ohmic or resistive heating and electrical arcing. More often arcing is preceded by heating.

So what are resistive heating and electrical arcing?

Resistive heating is the process by which the passage of an electric current through an electrical conductor produces heat. This heating phenomenon occurs in all electrical circumstances, yet is ‘controlled’ by awareness and good design.

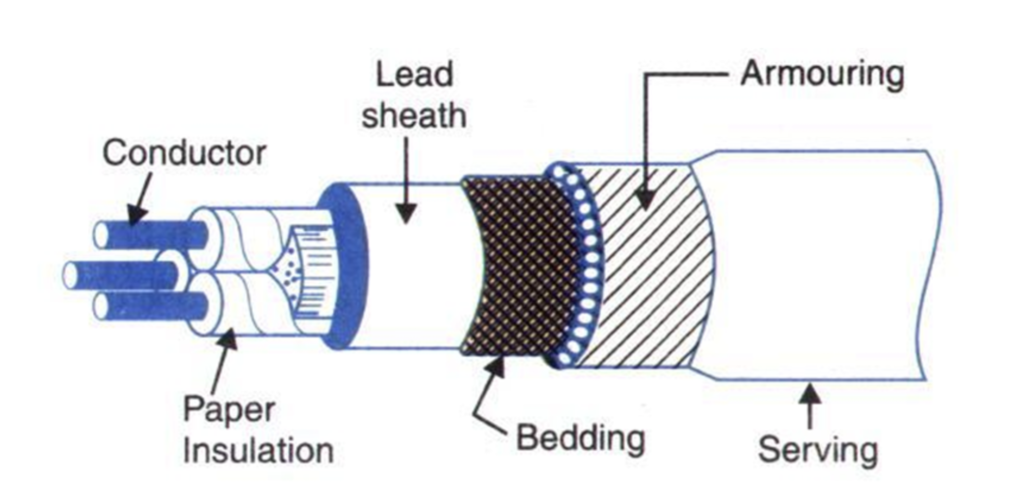

The ‘conductor’ or conductors, in the case a consumer unit are the electrical cables of the domestic electrical circuits, which terminate within the consumer unit. The electrical current is the entity, which flows around the domestic electrical circuits. A further electrical entity is electrical resistance is the entity that affords resistance to the flow of electrical current and given normal copper cables, the magnitude of electrical resistance will be low.

Now if the copper cable becomes damaged or ‘kinked’, electrical resistance increases with a consequence that electrical current flow decreases and resistive heating increases. This is similar to creating a ‘kink’ or restriction in a hosepipe when conveying water.

The effect of this is that if heat cannot be readily dissipated from the locality of increased resistance, i.e. the ‘kink’, heating will continue and temperature of the locality will increase to the point where most probably the plastic coating of the cable will melt, the surrounding pillow, cushion or duvet material begins to carbonise and scorch, and eventual flash point for fire ignition is reached.

Of course if heating still continues to attain the melting point of copper, the metallic constituent of the cable transposes from a solid to liquid and of course due to gravitational forces, parts of the molten copper cable will flow, i.e. physically part, creating an air gap in the once continuous solid copper cable.

One could assume that given an air gap that this would negate the process of heating since electrical current flow would cease. However, given sufficient electrical charge exists across the air gap, the air can ionise and start to conduct electrical energy once more. In simple terms air ionisation is the phenomena whereby air becomes a conductor of electricity, similar to the manifestation of ‘lighting’ in weather storms.

In these circumstance we refer to ‘small scale’ electrically induced lightening as ‘electrical arcing’, which is characterised as a plasma, which may produce intense blue/white visible light and exists at an extremely high temperature in the order of 20,000 oC, a sure fire igniting phenomena.

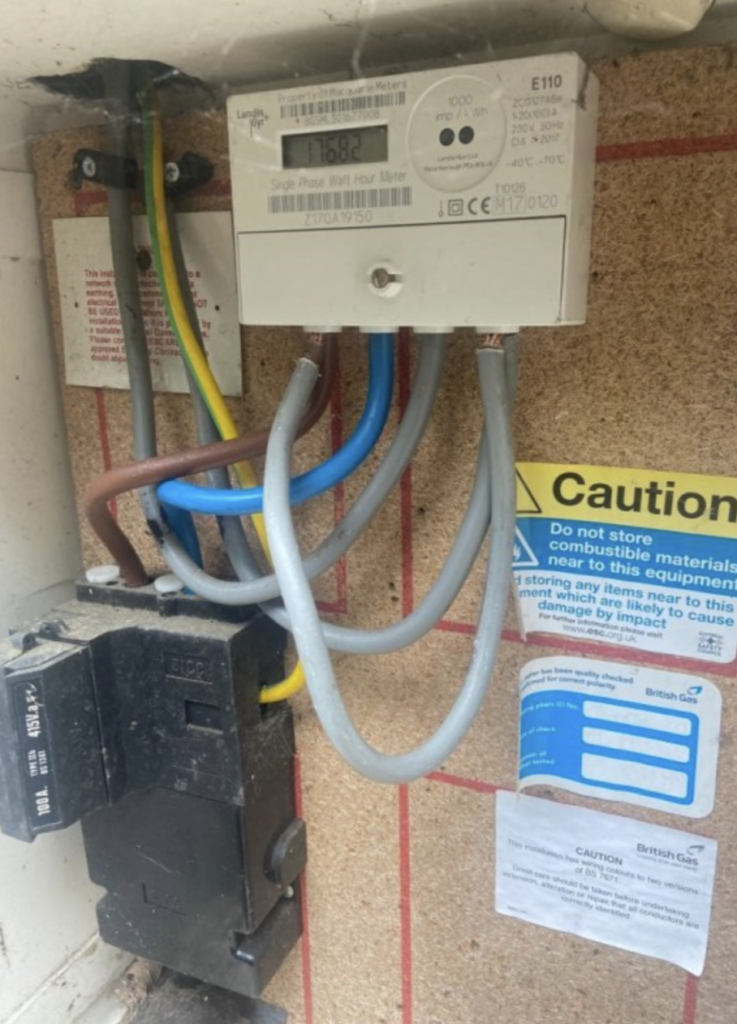

Of interest is the increase in report of fire ignition from the use of new ‘Smart Meters’, not that the meters are the cause of fire ignition yet that when installing the electrical consumption transducer of the meter, since this is attached to the main cables entering the consumer unit, and that most often the cables are difficult to access, physical ‘pulling’ of the cable, to attach the transducer provokes a ‘poor’ electrical connection.

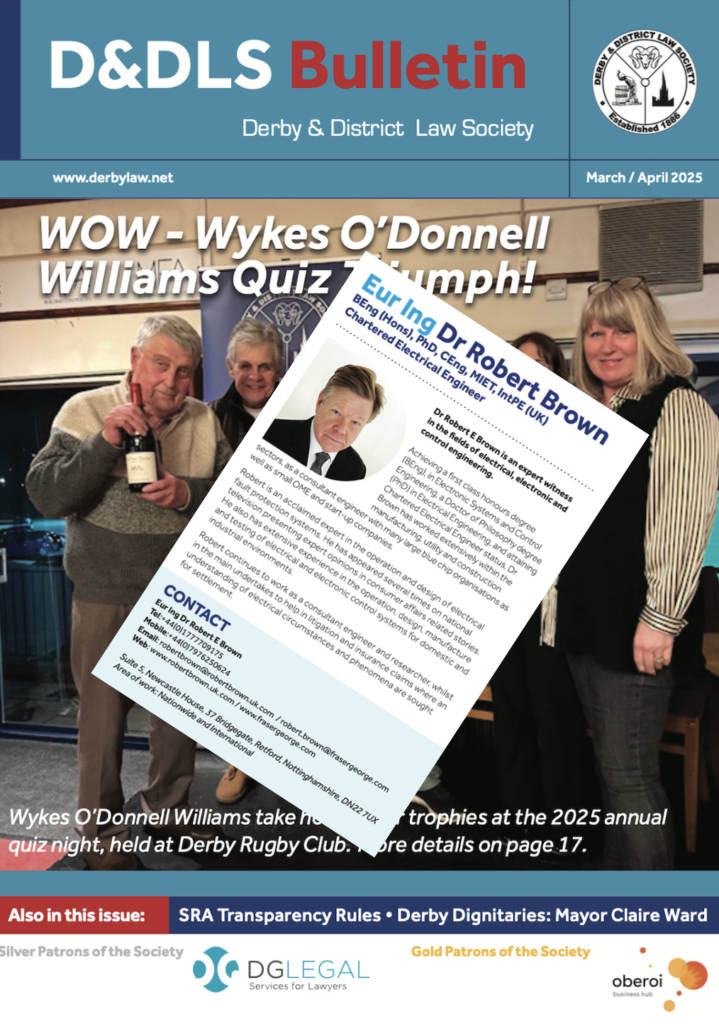

About Dr Robert Brown:

Eur Ing Dr Robert Brown (Robert) is the Executive Director of Fraser George and Associates Limited and is a Consultant and Forensic Engineer in the fields Electrical Electronic and Control Engineering.

Robert is an accomplished professional Electrical Engineer Expert Witness having prepared and presented many court compliant reports and presented oral evidence within the High Court, Crown Courts and County Courts.

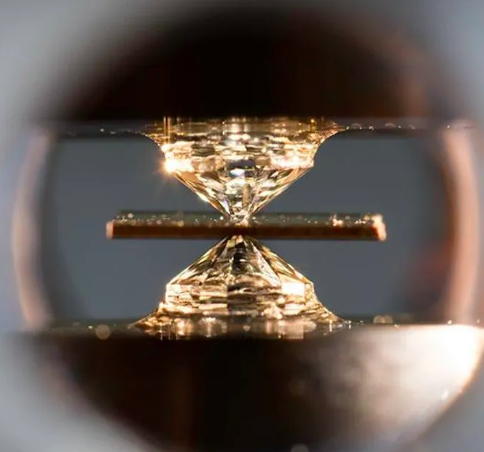

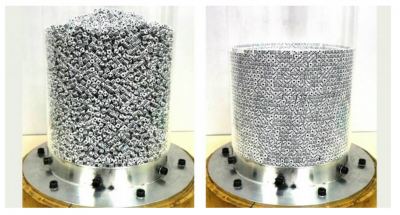

Robert is a registered Chartered Electrical Engineer, specialising in the fields are control engineering, parameter data capture and accurate data ‘representation’. Robert graduated from Sheffield Hallam University with a first class honours degree in Electronic Systems and Control Engineering and followed this by completing doctorate research in Electrical Engineering, again at Sheffield Hallam University where Robert undertook research studies in the field of Disintegration and Arcing in Electrical Fuses. Robert is now considered to be a leading world expert in the field of electrical circuit protection systems, the phenomena of electrical fuse operation and the attributes of clearing ‘fault’ electrical current circumstances. Robert has published my pure and applied research studies in peer-refereed journals and at conference.

In his spare time Robert is a Formula 1 motor racing enthusiast and enjoys outdoor activities especially hill walking and scrambling, golf and fishing. Robert is a brass band enthusiast, a tuba player and band manager of Hatfield and Askern Colliery Band. When time allows Robert also enjoys travelling and reading any books associated with travel and popular science.

Robert’s Curriculum Vitae:

https://drive.google.com/file/d/1GihZlqFQgqj2GUvJ6Qyq8C0qUk_ex9K1/view?usp=sharing

Robert’s litigation specialisms:

https://drive.google.com/file/d/1j82-viH_6kWaegdLl_GRRAFcEaHUm0wM/view?usp=sharing

Robert’s case portfolio:

https://drive.google.com/file/d/1xec5cowOe184V7ejCXKtHn8ELGKE0e3d/view?usp=sharing

Robert’s notable cases:

https://drive.google.com/file/d/11VUNbJOadHKOyEoOfY8xTZaAokElJAdH/view?usp=sharing

For further information please contact Robert via;

Email,…robert.brown@frasergeorge.com or robertbrown@robertbrown.uk.com

Tel Land: +44 (0)1777 709175

Tel Mobile: +44 (0) 7976250624

https://www.facebook.com/Fraser.George.Electrical.Expert

https://www.facebook.com/EurIngDrRobertBrown

https://www.linkedin.com/in/consultantrobertbrown

https://www.linkedin.com/company/21539092

Websites: www.frasergeorge.com and www.robertbrown.uk.com

https://frasergeorge.com/contact-us/

#ElectricalExpertWitness, #ElectricalEngineerExpertWitness, #ExpertWitnessElectricalEngineer, #ElectricalExpert, #ElectronicExpertWitness ,#ElectronicExpert, #ElectricalShock, #ElectricalRegulations, #ElectricalStandards, #ElectricalConsultant, #ConsultantElectricalEngineer, #ConsultantEngineer, #ForensicEngineerElectrical, #ForensicElectricalEngineer, #ElectricalRegulationsExpert, #ElectricalStandardsExpert, #ExpertElectricalEngineer,